THE NOVIQU BLOG

Maintenance Tips to Extend Equipment Life

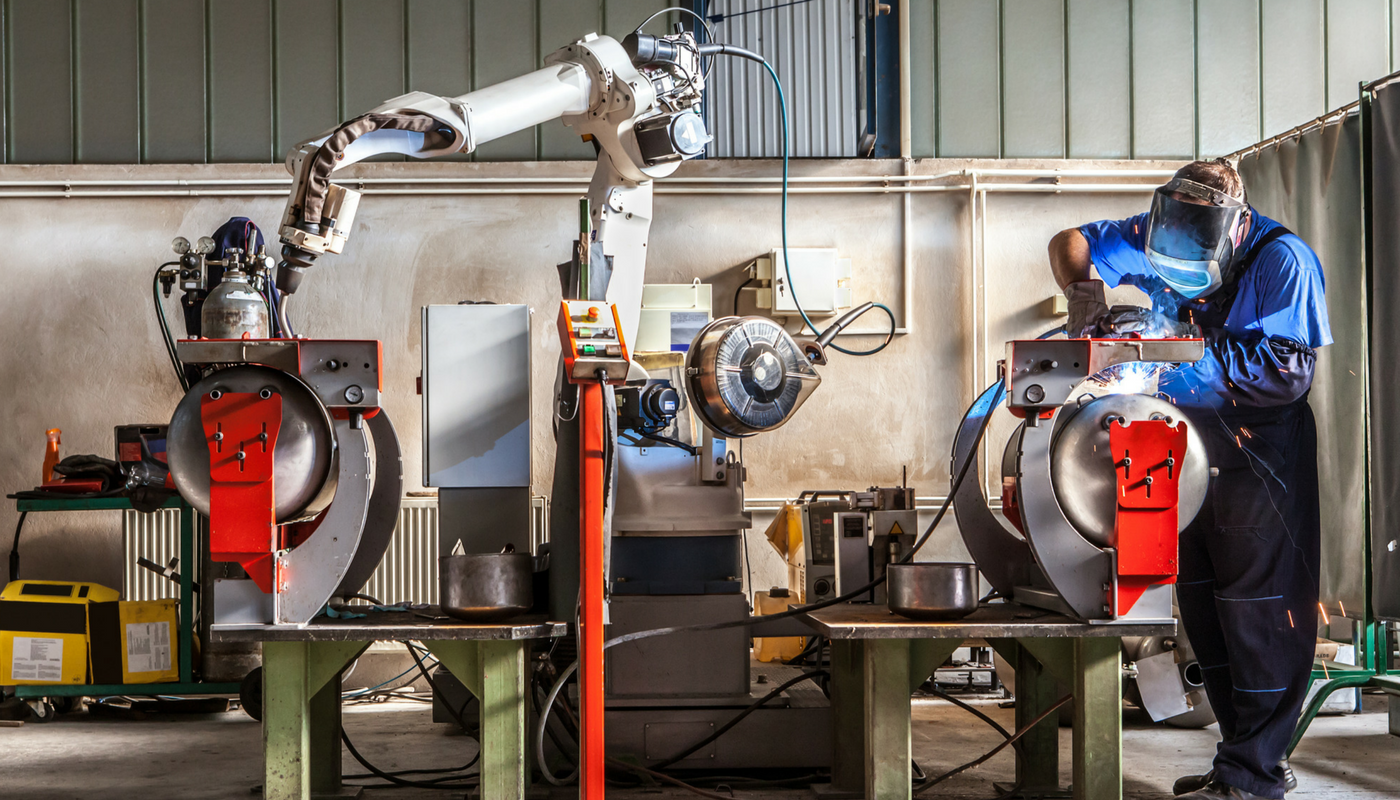

Be it manufacturing, construction, or warehousing - the equipment is the backbone of each of these industries. If one or more industrial machine were to suddenly break down, not only would it put a damper on productivity but it might just grind the entire operation to a halt. It should also go without saying that keeping the equipment in top shape will save the company thousands in repair costs and lost revenue, all the while keeping the workforce safe. Here are four maintenance tips to extend equipment life.

The Warranty

We cannot start this list properly without first addressing the warranty. Even though this is not a maintenance tip, per se, it is a crucial step in ensuring that the machinery lasts at least until you have your return on investment covered. If possible, negotiate all terms and conditions, as well as the length of the warranty up-front. Remember what the warranty covers and doesn't cover (or better yet, note that somewhere digitally) so that if something goes wrong, you won't have to pay for repairs that would otherwise fall under the responsibilities of the manufacturer.

Certified Repair Technician

While all machinery is prone to wear and tear, a machine’s lifespan can be greatly increased if proper personal training occurs regularly. An equally interesting idea would be to have a certified repair technician on staff, and even though machinery repairs shouldn't be a day-to-day thing, the technician can train other employees on the correct use, maintenance, and small repairs of the equipment.

In house repair technicians can help instruct line employees on the early warning signs that something is about to malfunction or fail completely. This way any potential problems will be reported early, ensuring that things will not degenerate any further and minimizing the risk of unexpected delays or costs.

Cleaning the Equipment After Use

Heavy equipment and machinery, in particular, have seals and filters in place to protect the many working parts from contaminants or other external particles. These should regularly be inspected to make sure that everything runs in perfect order. Breathers should also be kept clean as they can absorb contaminants and affect the electronics inside the cab. This, in turn, will affect the clutch and so on. Large machinery, such as forklifts, should be stored away from the elements. Leaving them in the wind and the rain will accelerate rust and other weather-related problems. Likewise, machinery should be run periodically if not regularly in use.

Check Lubricants Frequently

Proper lubrication is another key part of proper maintenance of your equipment. Lubricants have a wide range of uses such as reducing wear by separating moving surfaces, absorbing shock, reducing friction between moving parts, carrying the heat generated by friction, minimizing corrosion, keeping contaminants away, and the list goes on.

Look for signs of excess oil, grease build-up, or any signs of other fluid leakages. Check the oil seals regularly and make sure to use the right lubricant as each component may need something specific. Be sure to always follow manufacturer’s recommendations for lubricants.

Keeping your equipment and heavy machinery in top working condition is a sure-fire way to have a safe and properly functioning working environment. It is far better and cheaper to perform preventative maintenance regularly, and watch for early warning signs, than to have equipment failure and outages.

More

Posted on 03/11/2022

Noviqu appoints Austin Gardner as CTO

Posted on 6/20/2018 by Anna Haney

Going from Paper to Digital: The Noviqu Story

Posted on 03/03/2019 by Chad Haney